More often than not, foreign buyers just ask the supplier to produce their products referring to the prepared sample. But if you want to customize a product, this involves a higher and more specific requirement. First of all, a critical product analysis is required. Then, based on your request, make a review including the design, the package etc. Usually a skilled manufacturer is able to handle this with a set of professional strategies. Here we list some tips for your reference before confirming the Pre-Production Sample. After all, the pre-production sample will be the standard quality for your mass production.

1. Supplier Sample Assessment

Ideally, we could at least receive no less than 3 examples from our suppliers. Here is a case analysis. Let’s take this following product as an example which will show you how and from which angles to analyze a product.

Case study: Sample Assessment on T8 LED Tube

| Comparison | Supplier A | Supplier B | Supplier C |

| Photos |  |  |  |

| End Plug Component |  |  |  |

| Conclusion | ★★★ One end power supply | ★★ Two end power supply | ★★★ One end power supply |

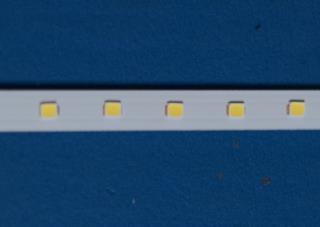

| LED |  |  |  |

| Conclusion | ★★ Total 88 LEDs, LED from Chinese manufacture | ★★★ Total 168 LEDs, from Taiwan Osram | ★★★ Total 120LEDs, from Chinese Sanan |

| Power Supplier Chip |  |  |  |

| Conclusion | ★★ Fix in the end plug with foam glue | ★★★ Protect with black foam tape | ★★★ Fix in the end plug |

| LED Base |  |  |  |

| Conclusion | ★★ PCB LED base is not a good enough choice | ★★★ An alumni LED base is good for releasing heat | ★★★ An alumni LED base is good for releasing heat |

Notice: Until now, you might have had a basic understanding of made-in-China products through the above case. Products from three factories were different though they were based on the same parameters.

Just think about that, you get what you pay for. Here in the above case, samples from supplier B and supplier C were much better. Choose the one that is of more compliance with your nation’s quality standard.

2. Sample Order Specifications Sheet

Commonly, many steps should be checked beforehand in order to secure the production process is in progress as expected. We think that the most important step, is to make a pre-production sample. That estimates the quality standard of the mass production. So you better spend enough time in coping with the pre-production sample.

Nevertheless, what we described here is just for your reference. You need to take various actions in different situations. After all, different products have different production procedures.

Case Study: Sample order specification sheet

A professional factory would send you a Sample Spec Sheet upon your request. That’s good for you. But in that case, you have to pay careful attention to those specified checklists under that sheet, because it includes the contract terms. So, you need to pay attention to the following points.

a. Set target

It’s Party A’s duty to make the required sample for Party B as per the contract. And the sample shall be strictly binding to all specified requirements. Party A shall not charge Party B any more than the agreed price unless Party B notices its amendment to the sample price.

b. Mould ownership (If any)

Party B owns the valid mould utilization and property rights. Whether Party A agreed or not, Party B possesses the right to retrieve the mould.

c. Protect your design

The package design, Party A shall not sell or provide the sample’s package and designs information to any third-party.

d. Intellectual property & confidentiality clause

Party A shall not use confidential information for any purpose or disclose any intellectual property involved information to any third-party.

e. Payment

Normally they require 100% in advance but we recommend 50% deposit paid in advance. 50% balance shall be paid off on Party B’s approval of the sample.

f. Termination

Party B may terminate the contract if Party A becomes unable to produce the sample, or doesn’t finish the production upon the expiration of time.

3. Sample Approval Checklist

You need to ensure that the sample is compliant with your standard, and is functioning well, or that it can be placed on your market, before you confirm it.

- Check if the functional requirements meet your product specifications.

- Check that the label, technical date and all specifications of the product sample are included.

- Check all test certification or reports before approving the product sample.

- Check whether the product sample meets your environmental and sustainability policy.

- Check if the product fulfills your “best value” criteria.